In previous posts we reviewed the origins and evolution of cannabis extractions, which have advanced significantly in the last twenty years, especially those techniques that use solvents such as ethanol and hydrocarbons.

This time we will talk about hydrocarbon extraction, the main organic compounds used to obtain cannabinoids.

If you have ever vaped a cartridge in oil, edibles or any product containing extracts, it is very likely that you have consumed a product derived from hydrocarbon extraction.

Our first impression would probably make us think that these are compounds that one would not want to ingest, however hydrocarbons have been used in food extraction for the past fifty years at least, especially in the production of flavors and colorants.

The purity & potency of hydrocarbon extracts vary widely; THC-rich extracts can be found containing between 90% and 95% of the plant’s original cannabinoids.

With proper & careful processing hydrocarbon extracts can be safe, both in terms of production and in the creation of products suitable for human consumption.

Hydrocarbon extraction generally involves propane as the primary solvent, although other hydrocarbons or a mixture of two or more may be used. When combined with cannabis plant material, the hydrocarbon dissolves the desirable compounds present in the plants.

In general terms the steps involved in hydrocarbon extraction are the following:

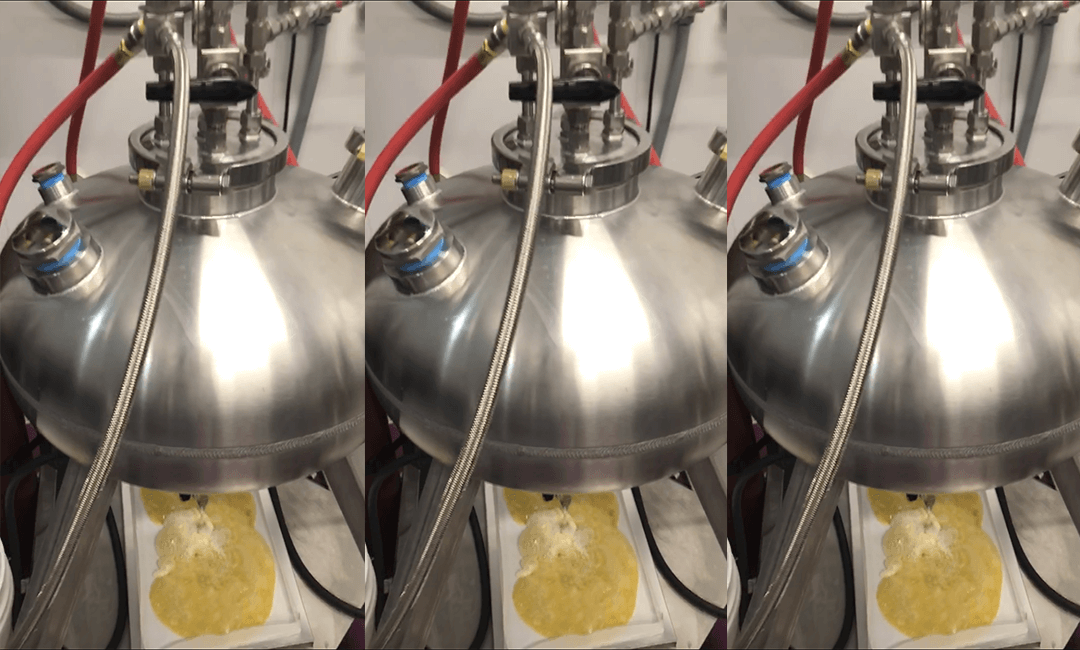

- Cold liquefied hydrocarbon mixture is used to wash the plant matter, dissolving cannabinoids (such as THC and CBD) and terpenes (which provide aroma and flavor), along with fats and waxes.

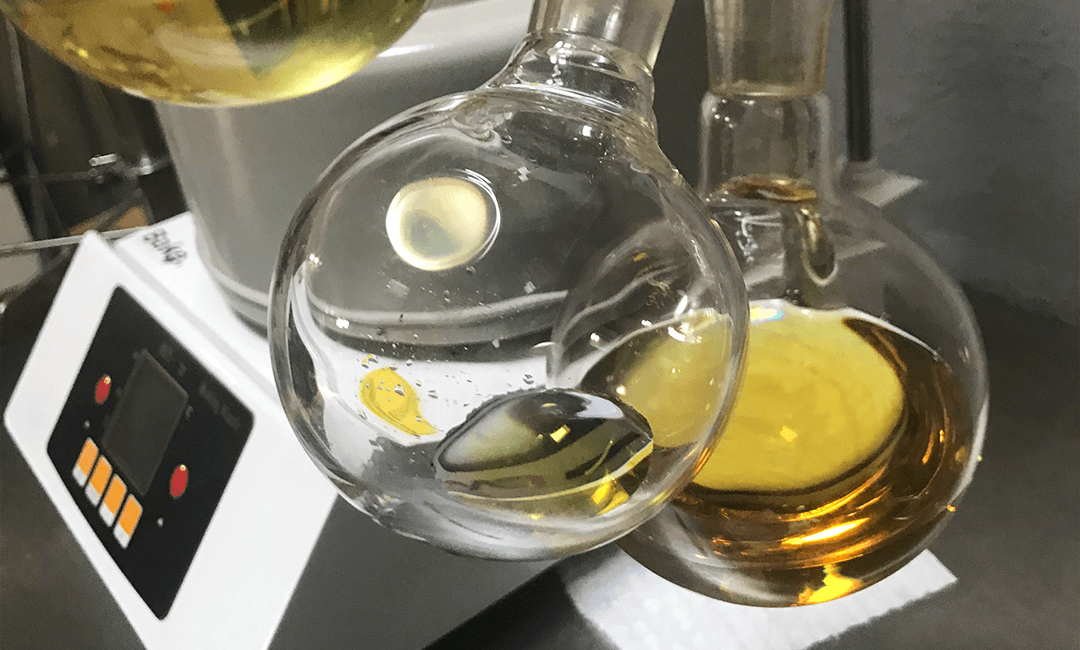

- The resulting solution can be refined using various methods, depending on the final product. For example, centrifugation, dewaxing and decarboxylation are other common refining steps.

- After refining, the resulting solution is passed through a collection chamber to remove most of the residual solvent. The butane is often transported back to the beginning of the process for reuse.

- Finally, the concentrated solution is further purged to remove any excess hydrocarbons. The process will depend on the final product, but may involve drying in a vacuum oven or churning

Butane offers a relatively simple and inexpensive method for extracting a large percentage of THC and other compounds.

One of the advantages of this method is that the authenticity of the strain is maintained. Each strain has a unique chemical profile that other extraction methods can make unrecognizable. Hydrocarbon extraction can maintain the delicate composition of the plant so that the original combination of cannabinoids and terpenes remain in the final product.

Another benefit is versatility. There are a variety of types of extracts that can be produced by hydrocarbon extraction because the levels of butane and propane can be adjusted to create the desired profile.

A further advantage of this process is that it allows more parts of the plant to be utilized. For example, trimmings from cannabis crops are often considered waste. However, the loose leaves still contain a lot of resin that is rich in cannabinoids. These and other components can be extracted by hydrocarbon extraction.

In the next post we will review some of the different products that can be extracted from hydrocarbon extraction.